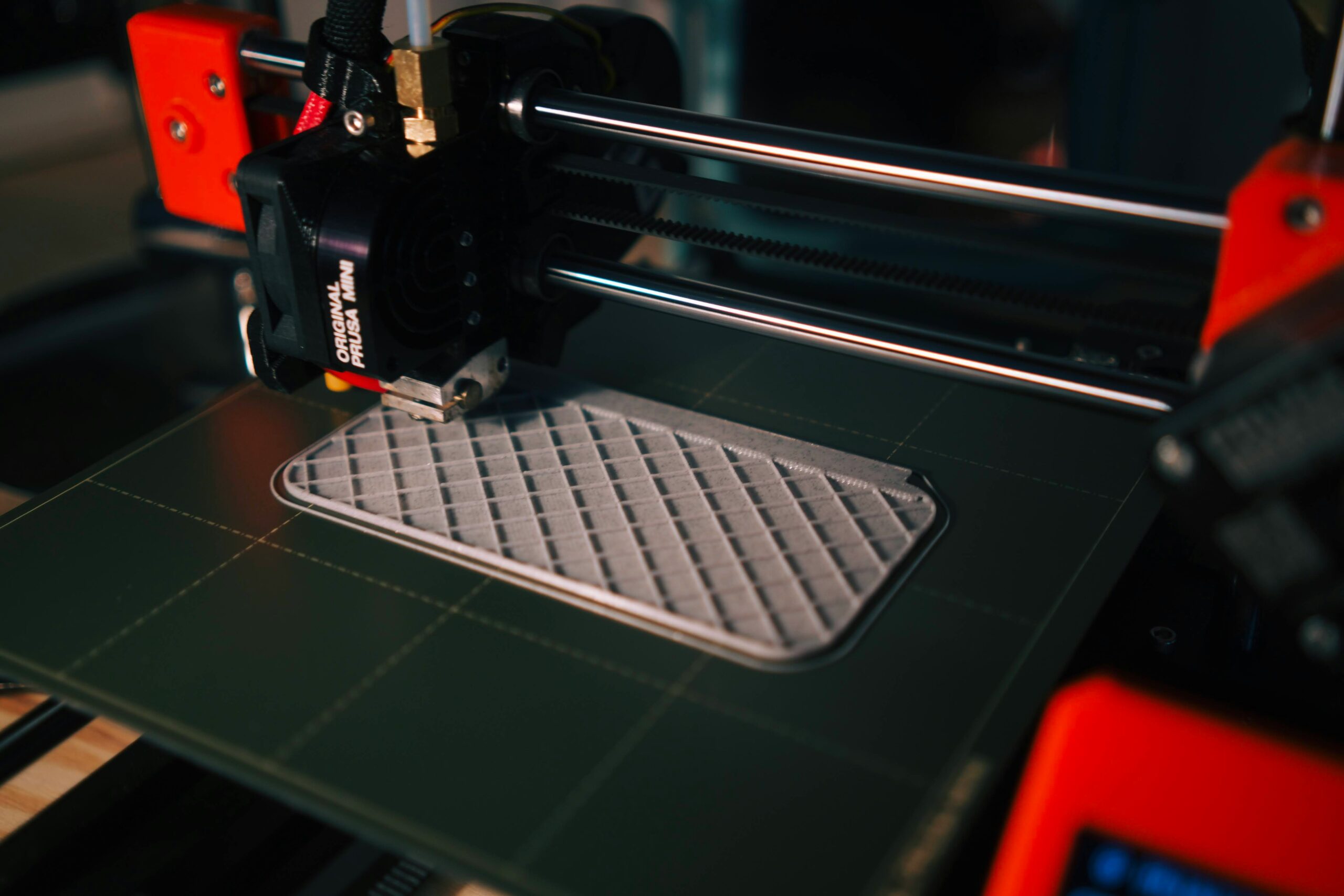

The construction industry has witnessed a significant transformation with the advent of 3D printing technology. One remarkable example of this innovative approach is the Wave House Data Center, Europe’s largest building constructed using 3D printing techniques. This groundbreaking project was completed in a record-breaking time of just 140 hours, revolutionizing the way we think about construction.

Traditionally, constructing large buildings would take months or even years. However, the Wave House Data Center has defied all expectations by leveraging the power of 3D printing. This cutting-edge technology allows for the rapid production of complex structures with unparalleled precision and efficiency.

The use of 3D printing in the construction industry offers numerous advantages. One of the most significant benefits is the reduction in construction time. By utilizing 3D printing techniques, the Wave House Data Center was able to achieve completion in a fraction of the time it would have taken using conventional methods. This not only saves time but also reduces costs associated with prolonged construction periods.

Another advantage of 3D printing in construction is the ability to create intricate designs and shapes that would be challenging or impossible to achieve using traditional construction techniques. The Wave House Data Center stands as a testament to the limitless possibilities of 3D printing, with its unique and eye-catching architecture.

Additionally, 3D printing allows for greater customization and flexibility in construction projects. With this technology, architects and engineers can easily modify designs and make adjustments as needed, without the need for extensive rework or delays. This level of flexibility ensures that the end result meets the specific requirements and vision of the project.

Furthermore, 3D printing in construction is an eco-friendly alternative. The process minimizes waste, as it only uses the necessary amount of materials required for construction. This sustainable approach aligns with the growing global focus on reducing carbon footprints and promoting environmentally friendly practices.

Despite the immense potential of 3D printing in construction, it is important to acknowledge that this technology is still in its infancy. While the Wave House Data Center is a remarkable achievement, there are still challenges to overcome and further advancements to be made. However, this project serves as a catalyst for future innovation and paves the way for a new era in the construction industry.

As 3D printing continues to evolve, we can expect to see more groundbreaking projects like the Wave House Data Center. The possibilities are endless, from constructing sustainable housing to creating intricate architectural masterpieces. The future of construction is being shaped by this revolutionary technology, and it is an exciting time to witness its growth.

In conclusion, the Wave House Data Center stands as a testament to the power of 3D printing in the construction industry. With its rapid construction time, intricate designs, flexibility, and eco-friendly approach, this project has set a new standard for construction practices. As we look towards the future, it is evident that 3D printing will play a pivotal role in shaping the buildings and structures of tomorrow.