The semiconductor and semiconductor industries are poised to transition into a unique era with the use of glass substrate in the coming years. Now, Samsung is taking steps in this direction.

For quite some time, the semiconductor industry has been embroiled in a race measured in nanometers, with innovation taking a back seat. As the nanometer race encounters technological and physical challenges, the boundaries of organic materials are also being pushed. However, giants like Samsung and Intel have been working on solutions to overcome these hurdles and usher in a new era in semiconductors with glass substrates. According to recent reports, Samsung is expected to commence production of glass substrates by 2026.

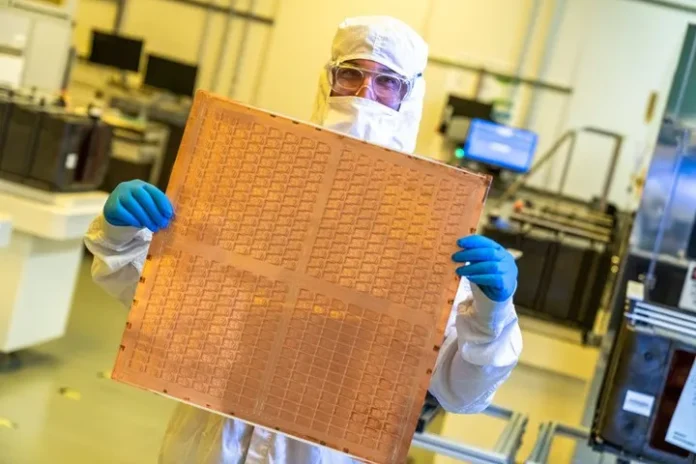

The concept of glass substrates came into the spotlight last year, with Intel leading the charge. Intel showcased initial demo samples at its glass substrate packaging facility, aiming to deliver complete glass substrate solutions starting from the latter half of this decade and targeting to provide 1 trillion transistors on a single package by 2030. However, Samsung aims to outpace Intel with its 2026 goals.

Samsung Electro-Mechanics is accelerating its efforts in semiconductor glass substrate market with equipment procurement and installation activities. The company plans to open a pilot production line for next-generation packages in the fourth quarter. Additionally, Samsung has already chosen suppliers for its upcoming projects. The goal is to transition to glass substrate production for advanced package-on-package systems (SiP) by 2026.

Glass substrates offer significant advantages over traditional organic substrates, including superior thermal, physical, and optical properties, as well as up to 10 times higher interconnection density increase. Moreover, compared to modern organic substrates, glass can provide 50% less pattern distortion, enhancing focus depth. These initiatives by Samsung Electro-Mechanics are expected to be invaluable for Samsung Foundry in the future.